Simulation Methods

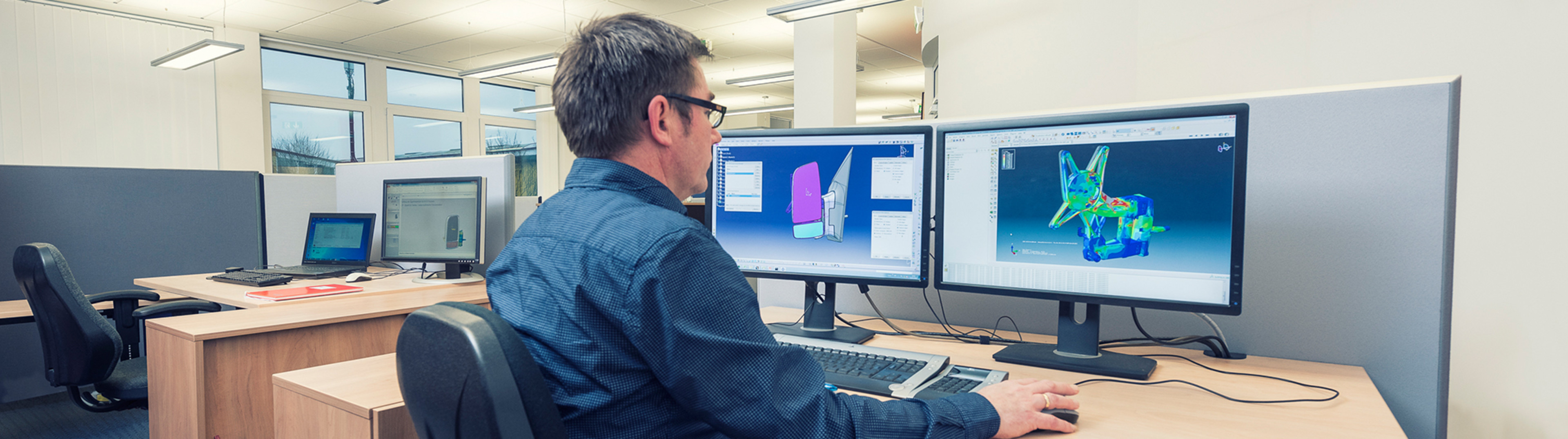

We use state-of-the-art computer-aided engineering (CAE) software in the early stages of component and assembly design. This enables us to meet our customers’ and our own highest requirements using a minimum of resources.

At MEKRA Lang, testing and computational engineers work together closely, both spatially as well as professionally, resulting in continuous improvement and validation of our computational methods.

FEM / Topology

Simulations at MEKRA Lang are based on the Finite Element Method (FEM). We determine the vibration properties, strength and useful life of our products even before using prototype parts, and we employ topology optimization techniques to improve the wear-and-tear properties of structural components.

This approach enables us to minimize risks and to leverage any optimization potential at an early stage. It gives us the ability to evaluate and implement improvements quickly, economically and effectively for the benefit of our customers.

Moldflow

Before we go into production with any of our newly developed plastics parts, we perform simulations with the injection molding simulation software Moldflow. Using Moldflow, we simulate the fill patterns for plastic parts, determine whether wall thicknesses are appropriate for plastics and calculate the best possible injection point, which is a critical factor for component quality. Should permanent component warpage prove to be unavoidable despite optimization steps during the initial planning stage, we design the component in a way that offsets the calculated warpage and produces an optimized part.

Aerodynamics

Using Computed Fluid Dynamic (CFD) simulations, we evaluate the flow dynamics of various design options, which allows us to optimize the component geometry.

Thermal Heat Propagation

Thermal heat transfer simulations provide us with valuable insights for the development of electronic components and assemblies. This enables us to determine optimized heating and cooling concepts already during the design phase.

The close collaboration and integration of our mechanics and electronics departments allows us to analyze the thermal properties of new design concepts quickly and efficiently and to make any changes or adjustments as needed.